In an earlier post we went through how beef is raised and finished, but what happens after that? We’re glad you asked, because while we’re deeply invested in the entire supply chain, the “after” is where our passion lies.

BUT WHAT DOES “MEAT PROCESSING” ACTUALLY MEAN?

“Processing” refers to the workflow from harvest—or slaughter—all the way through to finished products. In the context of the beef industry, this means turning live cattle into the high-quality beef customers are thrilled to buy!

The steps generally flow in this order: Stun, bleed, hang, remove the hide, eviscerate, split into sides (halves), cool, age, and finally, break the carcass down (i.e., cut or fabricate) into the meat products customers need: Primals, subprimals, trim, retail case-ready, etc. There are different points of inspection throughout this process depending on where and to whom the products are sold—learn more about that here.

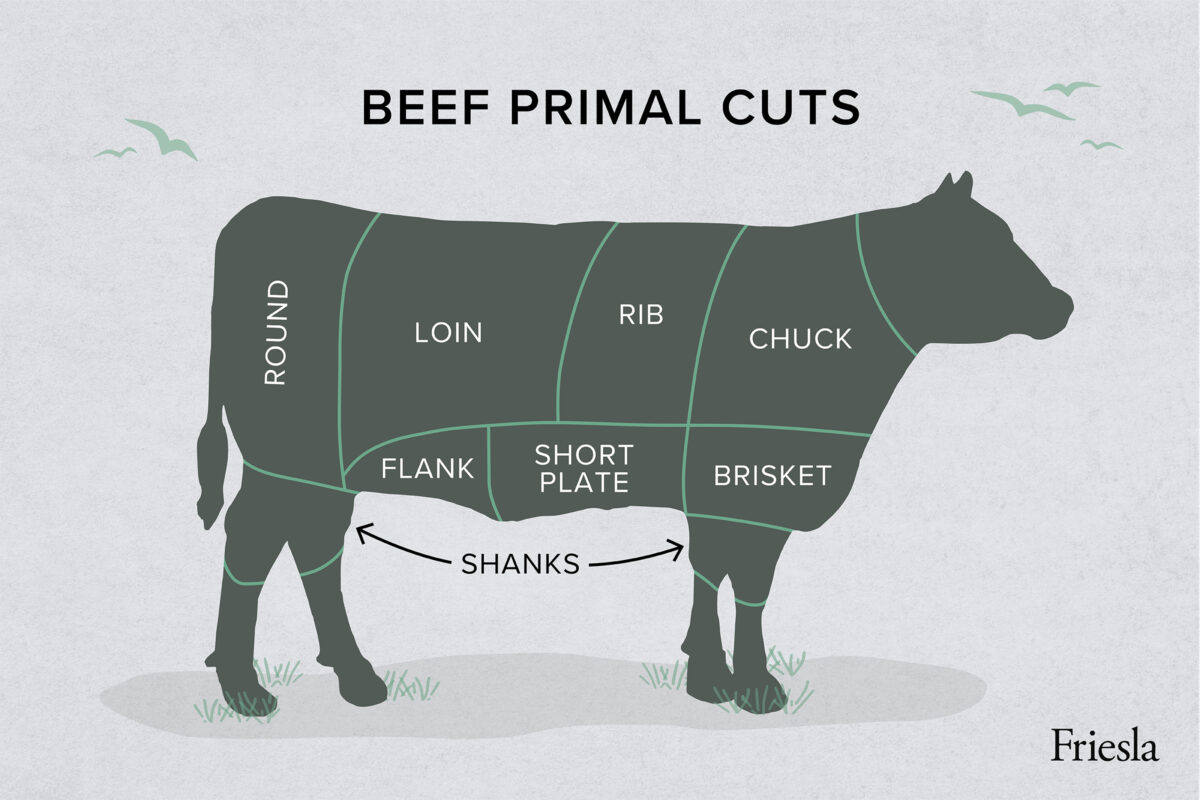

Primals are the first division of the beef carcass and the largest cuts: Shank, Brisket, Rib, Short Plate, Flank, Round, Chuck, and Loin. Subprimals are the next division, and include cuts like Ribeye, Strip Loin, and Bottom Round. Subprimals can be further divided into many of the cuts you’re used to seeing at the grocery store, like Ribeye Steaks and Roasts, T-Bone and Porterhouse Steaks, and Round Roasts. Trim consists of the meat trimmed off of finished cuts (“bench trim”) and the remaining meat after all desired cuts are removed. It’s often made into ground beef or ready-to-eat products like beef sticks. How each carcass is broken down depends on the end user: are cuts going to be sold in a retail setting, to a restaurant, or somewhere else?

Knowing what the customer needs before starting this process is key to remaining efficient, ensuring a market exists for the products you plan to create, and ensuring customer satisfaction all the way to the end consumer.

THE TRADITIONAL ROUTE

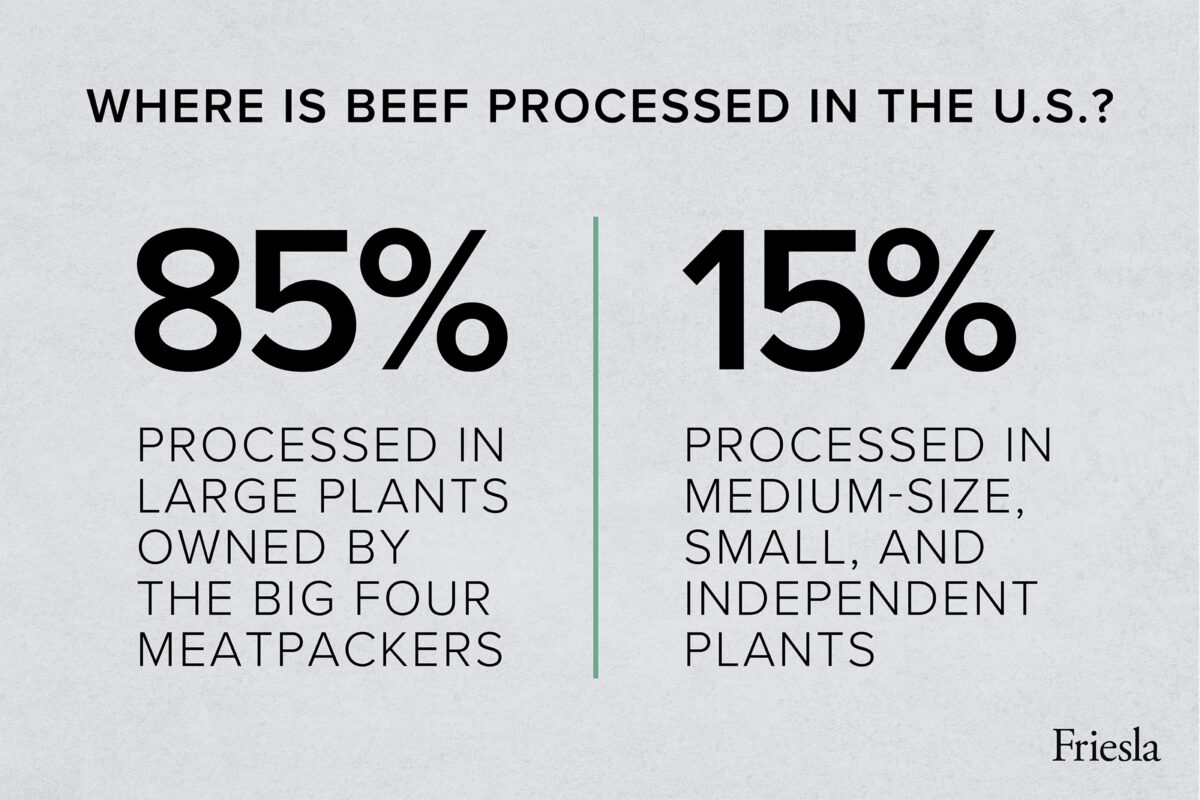

After cattle in the U.S. are finished and ready for processing, the majority—about 85%—are processed in large packing plants owned by one of the Big Four meatpackers. Learn more about industry consolidation here. All of the nation’s large meat processors—who have a slaughter capacity of 5,000+ head per day—are owned by the Big Four.

The remaining 15% of cattle are processed by medium-size, small, and independent processors. A medium-size processing plant is one that processes between 1,000-2,000 head per day, while small plants are classified as 1,000 head per day or less—and typically much less.

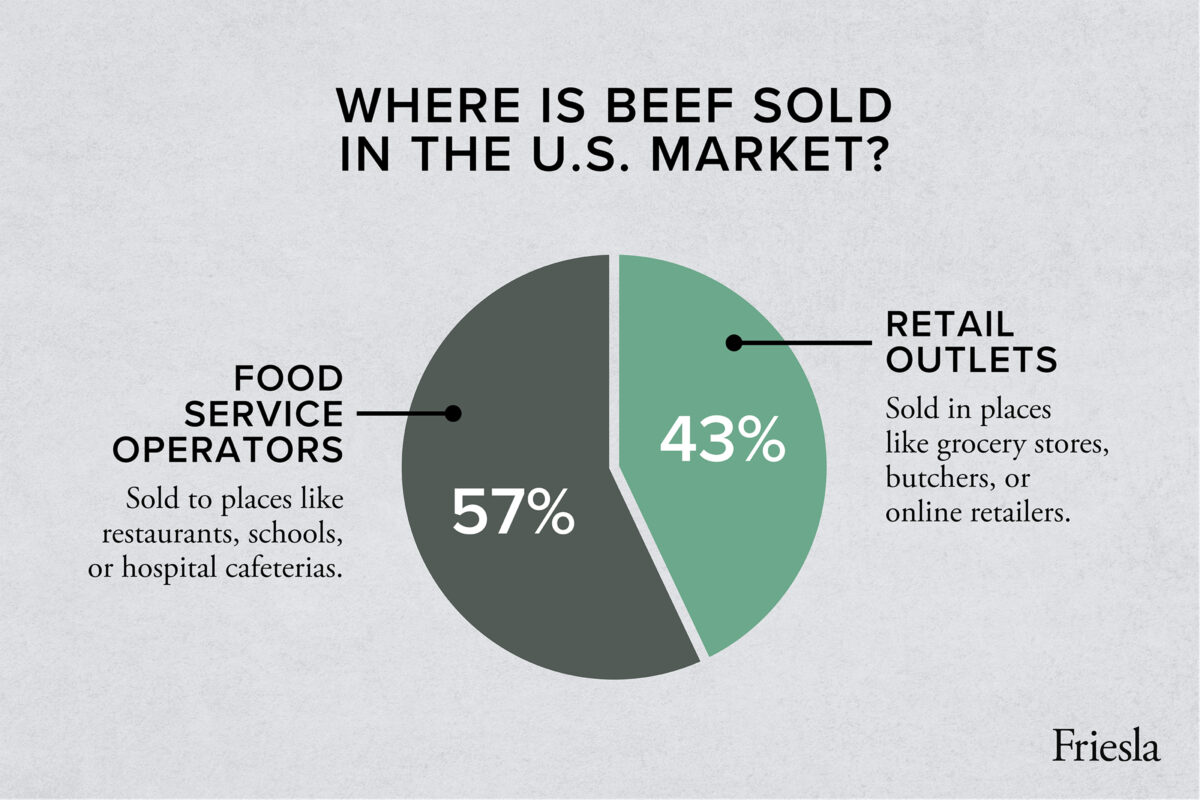

All beef reaches U.S. consumers via a retailer or food service operator. This can be from a wholesaler or distributor who buys direct from a processor or from a further processor (e.g., a company that buys trim to produce ground beef).

From all the beef sold in the market, 57% goes to food service operators, of which the majority (60%) is ground beef. Food service operators range from restaurants to schools or hospital cafeterias. The remaining 43% of beef sold in the market goes to retail—e.g., grocery stores, butchers, or online retailers—and is split fairly evenly between ground beef and steaks, roasts, etc.

OPPORTUNITIES FOR INDEPENDENT PROCESSORS

Complex regulation and policy changes in the U.S. over the past 50+ years has contributed to ongoing consolidation in the meat industry. Meat shortages and the increase in demand for local meat processing during COVID highlighted the issues with centralized processors.

The monthslong—and often yearslong—wait times to get animals processed locally, however, proves the demand exists for more independent, small meat processing plants. The increase in consumer demand for traceable, high-quality food provides additional incentives and opportunities—for several groups:

- Meat producers who want to vertically integrate and add processing to their operations

- Meat processors who want to expand their current processing capabilities or capacity

- Entrepreneurs who want to make an impact in their local and regional food space

FRIESLA IN THE FIELD

A big barrier to entry for operators who want to get into meat processing or expand their current scale is infrastructure. Traditional stick-built plants are costly, require a knowledgeable team for design and engineering, take years to build and get up and running, and are difficult and expensive to expand. Friesla’s Mobile and Modular Meat Processing Systems provide an alternative that enables you to begin multi-species processing more quickly—and with flexibility to expand, move, or rearrange as you grow.

MTXBeef in Texas, The Meating Place in Oregon, and Five Marys in California are great examples of niche meat processors that use Friesla Systems to produce high-quality, traceable meat and serve their local communities. MTXBeef purchased a preowned Friesla PS System during the pandemic to vertically integrate their beef production operation, while Friesla helped The Meating Place expand its butcher shop offerings to include on-farm slaughter and branded meat products. Five Marys Ranch already had a brick-and-mortar fabrication facility, but was missing the humane and thoughtful harvesting component. A Friesla Mobile Harvest Unit now gives Five Marys full control over how their beef and pigs are harvested, and enables them to do so on-ranch.

Whether Mobile or Modular, Friesla’s USDA-compliant Systems are a complete solution:

- Designed and built for multi-species meat processing and to your specifications—harvest, chill, cut, pack, freeze, and store finished goods on your site

- Outfitted with all processing equipment, traceability hardware and software, and consumables—ready for startup

- Complete with the HACCP plan writing, training, and support you’ll need to operate under Federal or state inspection

THE FUTURE OF MEAT

Domestic and global meat consumption is on the rise. Customers ranging from home cooks to elite chefs are demanding higher-quality, local, traceable food—whole, clean products they can trust. There are also growing conversations around food system resilience, farmer and rancher livelihoods, and how to facilitate positive change amid the consolidation of the food system. Independent meat processors are integral to these concerns and need support to survive and succeed: from consumers in our communities to regulators in office. At Friesla, we’re working hard to provide you tools to take back control of local meat processing—on your terms, time, and site. Together, let’s get started.