Designing, engineering, permitting, and constructing a new building can be costly and time-consuming. A meat processing plant is no exception.

Meat producers may consider building a brick-and-mortar meat processing facility to vertically integrate their operations. Existing meat processors looking to expand their businesses might also explore breaking ground on new construction.

Friesla’s Mobile Meat Harvest Units (MHUs) or, more simply Mobile Harvest Units, provide meat producers and processors an alternative: a USDA-compliant, self-contained slaughter floor on wheels.

Friesla’s Mobile Meat Harvest Units (MHUs) provide meat producers and processors an alternative: a USDA-compliant, self-contained slaughter floor on wheels.

Several advantages of Mobile Harvest Units versus fixed structures cited by the USDA include:

- Lower processing costs

- Reduced stress on animals

- Lower capital investment

- Less resistance from municipalities and neighbors

DEFINING “MOBILE”

The USDA defines Mobile Harvest Units—known in their terms as Mobile Slaughter Units (MSUs)—as self-contained slaughter facilities that can travel from site to site. Though MHUs can be moved, however, their operators don’t necessarily need to regularly move them.

In some counties, the construction of a new brick-and-mortar meat processing facility is explicitly prohibited by permitting and zoning regulations. For many producers and processors across the U.S., mobile meat processing trailers may be the only viable option for adding a kill floor or increasing their existing slaughter capacity.

OPERATING UNDER USDA INSPECTION

Since 2005, Mobile Harvest Unit owners and operators are eligible to apply for a USDA Grant of Inspection—just like traditional meat processing plants. For example, Bear Mountain Beef, a meat processor in Wyoming, brought their vision to reality in 2021 during the COVID-19 pandemic, obtaining a federal Grant of Inspection for their small meat processing plant, which includes a Mobile Harvest Unit. Hear about Mac and Celsie Sussex’s journey in their own words here (starting at 3:38 on the YouTube video recording).

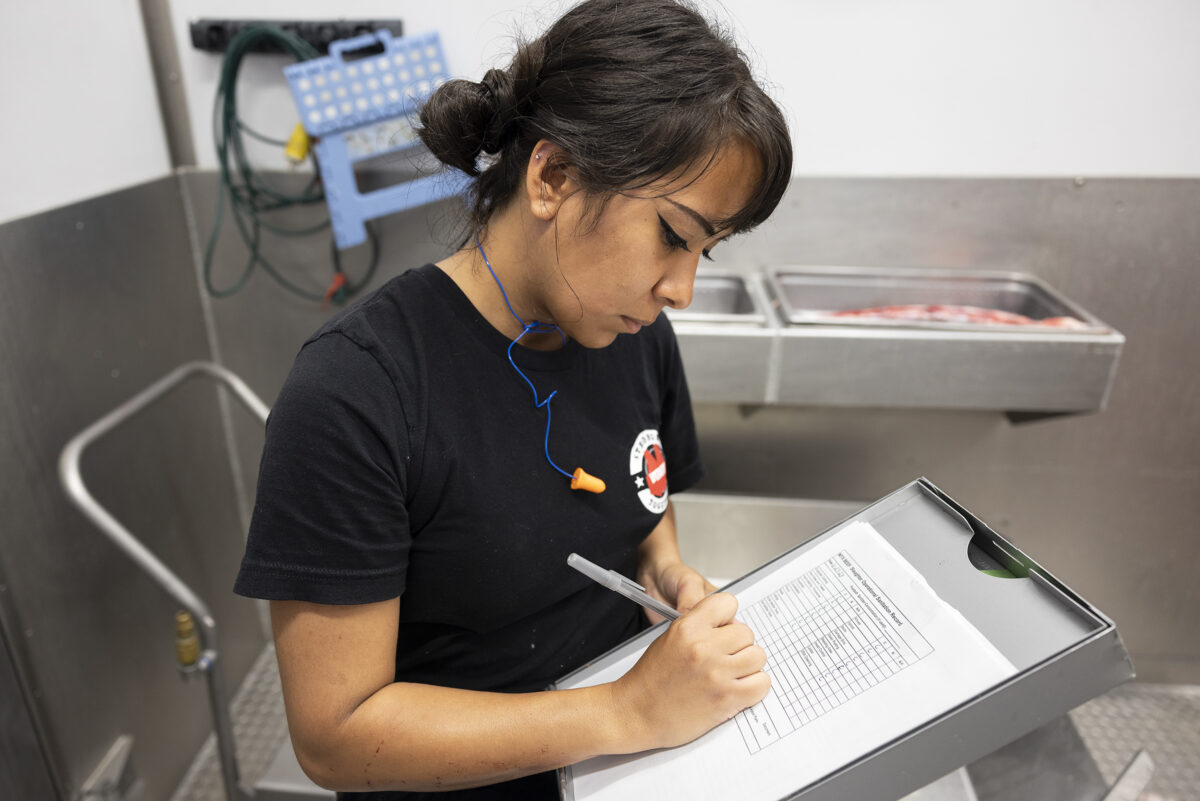

MHU operators like Bear Mountain Beef are responsible for meeting all regulatory requirements for the humane slaughter of livestock. They must also implement and maintain Sanitation Standard Operating Procedures—aka Sanitation SOPs or SSOPs—and a Hazard Analysis and Critical Control Points (HACCP) Program. A USDA inspector must approve the facility conditions before slaughter begins and must be onsite when each animal is harvested.

MHU-SPECIFIC COMPLIANCE

MHUs are still subject to regulatory requirements under USDA’s Food Safety and Inspection Service (FSIS) oversight. FSIS provides specific compliance guidance for mobile slaughter in a number of areas unique to MHUs. Key examples include:

- Multiple Locations: The MHU owner/operator is responsible to file an application for inspection with the USDA District Office (DO) of the geographic area in which the facility will primarily operate. If the MHU will be operated at locations in multiple districts, an application for inspection must be filed for each location. Click here for a list of DO locations and contact information.

- MHU Placement: The grounds surrounding the MHU location(s) must be maintained to prevent unsanitary conditions that may lead to spoiled products. For example, positioning the MHU on a well-draining concrete or gravel pad can help control manure, mud, pooling, water, and prevent other sanitation issues.

- Water: MHUs can use municipal water supplies, private well water, or water trucked in and put in a tank on the slaughter site. In all cases, documentation that proves the water is potable must be available for FSIS review at each operational location.

- Sewage & Waste Water Disposal: MHUs might not have access to traditional sewage facilities. Disposal can be adapted for the specific situation in accordance with local health authority oversight.

- Additional Carve-Outs: The USDA acknowledges the unique nature of mobile and small meat processing facilities and offers several accommodations to typical regulations. For example, meat rail heights are permitted to be slightly lower, and eviscera/offal are permitted to drop to the floor.

CHOOSING MOBILE HARVEST

Building a traditional brick-and-mortar facility can have a high price point and drawn-out timeline. Construction may be prohibited altogether by local permitting and zoning regulations.

In lieu of a new stick building, Mobile Harvest Units support multiple meat producers in areas where slaughter services are unavailable or slaughter dates are booked out months—or years. Adding slaughter capacity helps producers and processors to meet increased consumer demand, expand their businesses, and bring jobs into local communities.

Adding slaughter capacity helps producers and processors to meet increased consumer demand, expand their businesses, and bring jobs into local communities.

From plant design and site plan development to writing HACCP plans and gaining federal or state inspection approval, Friesla’s team guides you through the process of deploying your Mobile Harvest Unit—from concept to operations.

Learn more about Friesla’s Ecosystem of Services or connect with us here.