Meat harvest, fabrication, packaging, and sanitization generates waste byproducts: from bones to blood, heads, hides, inedibles, offal, and wastewater. In another blog post, we covered creating value-added products from meat processing waste. But what’s a small meat processing plant to do with all of that wastewater from harvest, processing, and cleaning up afterward? It’s a key consideration since managing wastewater is vital to maintaining a clean, safe, and compliant operation.

Mobile Harvest Units and Modular Meat Processing Systems have different requirements, primarily because mobile meat processing—starting with mobile slaughter—may be an intermittent occurrence compared to harvest-to-package processing in modular meat processing units which, despite being moveable, are typically secured/fixed to a foundation. The volume and frequency of wastewater generation at a fixed facility requires a strategy, so this blog post will mainly cover considerations for modular meat processors.

WHO MAKES THE RULES?

Since meat processing involves food and animals, it is heavily regulated by the USDA. One might infer that USDA’s rules for water and wastewater are stringent, but here’s the long and short of it:

USDA requires a meat processing facility’s water to be tested for potability to ensure it is safe and drinkable. This testing is done on an annual or biannual basis, depending on the type of water source. However, the USDA does not regulate a meat processing facility’s wastewater outside of ensuring the facility has required wastewater-related permits in place and complies with USDA’s Sanitation Performance Standards (CFR 9 part 416 section 1-6).

Understanding what your county requires, or how wastewater regulations differ between counties in your state/region, is a key part of planning to launch your meat processing facility.

Wastewater regulations are made at the federal, state, and local levels by water quality control commissions, the EPA, and similar government entities. These regulations can vary significantly between geographic areas, and there are a lot of nuances in these differences. If you’re exploring starting your own small independent processing plant or adding a Friesla System to your operations, a good first step is to research and become familiar with your local wastewater regulations.

Wherever you’re located, there will be some form of wastewater regulation. Understanding what your county requires, or how regulations differ between counties in your state/region, is a key part of planning to launch your processing facility. If you have multiple site options and flexibility in location, educating yourself on the wastewater regulation differences between locations in your area may also help inform your decision on which site to choose—and potentially net you cost and time savings.

FIVE OPTIONS FOR WASTEWATER MANAGEMENT

Depending on local regulations, a meat processing facility operator will likely have options for managing wastewater. Wastewater management typically falls into one of these five methods:

- Modified septic system (the most common)

- Municipal sewer/wastewater system (provided it can handle higher levels of BOD)

- Wastewater lagoon or evaporation pond

- Temporary storage and trucking to an approved off-site facility

- Anaerobic digester (if one is located nearby; e.g., on a dairy farm)

Each of these methods comes with different considerations. For example, septic and municipal sewer systems require a grease interceptor or settling tank to separate liquids and solids (fat, oil, and grease) before the water continues to the septic tank or the water treatment plant. In contrast, a wastewater lagoon or evaporation pond may require a larger physical footprint and more involved work on the site infrastructure.

Most of these options require the separation of blood and water via a blood collection tray, which enables you to remove up to ≈99% of the blood from the remaining wastewater. It’s also a general rule to pick up any visible pieces of meat, offal, and inedibles for disposal, composting, or rendering instead of washing them down the drain. Failing to separate enough of the blood or solids out of your water could overload your septic system—potentially leading to costly repairs or more frequent maintenance—or make your lagoon or pond less efficient by requiring more frequent sludge removal.

BUILDING YOUR PLAN

Sorting through wastewater regulations and management methods can be intimidating. Beyond your own research into local rules and potential methods, we’ve seen Friesla clients find value early on in the process by engaging with a local wastewater engineer or firm who knows your county regulations and can help you sort through options. Having a knowledgeable, local advocate in your corner goes a long way.

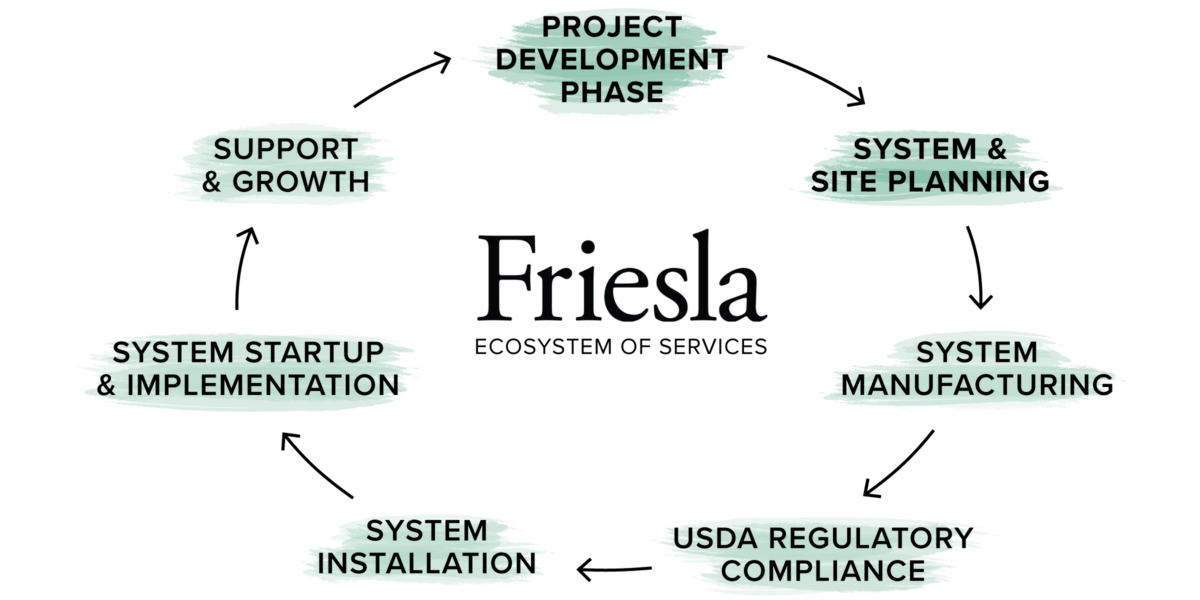

For Friesla’s part: during your Project Development Phase, our Technical Team works with you to design a Mobile or Modular Meat Processing System that efficiently integrates with the wastewater management plan you choose. As you nail down your plan and secure local contractors to complete site infrastructure work related to your wastewater treatment, our Technical Team will assist with information sharing—from estimating water usage and wastewater output based on your processing volume and System design, to coordinating with you and your contractors on how your chosen method integrates with a Mobile or Modular System.

LESS WATER & WASTEWATER

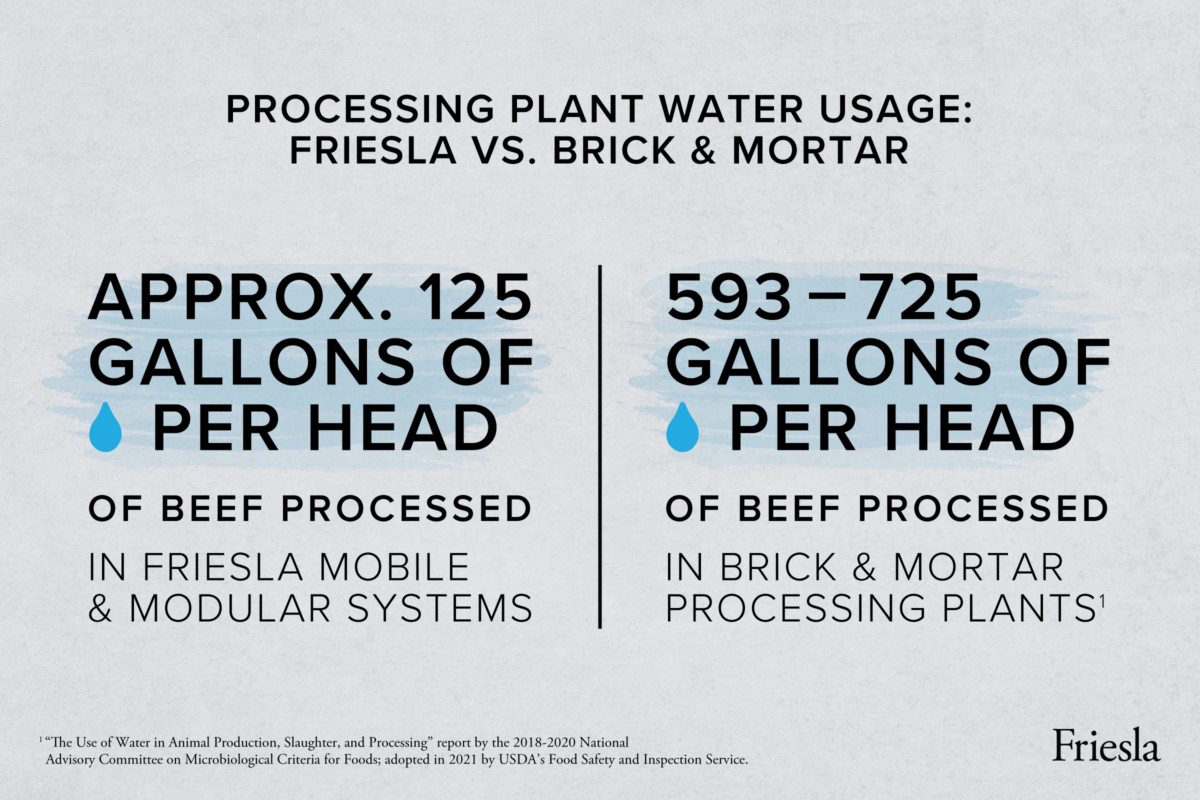

Working through your Project Development Phase and wastewater management will also highlight a key advantage of your Friesla System: efficiency in water usage and wastewater generation. Friesla Systems are constructed with non-porous, USDA-compliant materials and require significantly less water for operations compared to a traditional brick-and-mortar meat processing plant. On average, Friesla Clients operating at or near System capacity use approximately 125 gallons of water per head of beef processed—based on an average 1200 lb live weight.

In contrast, a report by the 2018-2020 National Advisory Committee on Microbiological Criteria for Foods titled The Use of Water in Animal Production, Slaughter, and Processing—adopted in 2021 by USDA’s Food Safety and Inspection Service (FSIS)—discussed water usage in traditional brick-and-mortar meat processing plants. Table 1-1 titled “Estimated amount of water used during processing by species” (page 53, lines 1422-1425) compiles data from several research papers, including Li et al. (2018) and Warnecke et al. (2008). The most recent data—Li et al.—showed brick-and-mortar plants used between 593-725 gallons of water per head of beef processed. All other brick-and-mortar plants researched either fell in a range between 500-725 gallons per head range or far exceeded it—with an outlier even extending to 1,613 gallons per head (Warnecke et al., 2008).

THE BOTTOM LINE

As it relates to meat processing facilities, wastewater regulation is handled by many different organizations and can vary greatly by location. A sound wastewater management plan is both required and can save meat processors a lot of time and trouble.

Compared to traditional brick-and-mortar plants, Friesla Systems require less water to operate, generate less wastewater, and are designed to support a variety of wastewater management methods. During Friesla’s Project Development Phase, our Technical Team stands ready to support as you craft your waste management plan—whether by estimating water usage, wastewater output, or advising on management methods and processes. To learn more, connect with us here.