Meat Processing Systems

Consumer demand for locally-grown specialty meat products is exploding. However, the meat industry continues to consolidate under the weight of big corporations. The alarming decrease in USDA and state-inspected slaughterhouses is forcing small meat producers and processors to be beholden to the behemoths. At Friesla, we’re providing farmers and ranchers an alternative: Meat Processing Systems that enable your complete control over onsite meat processing—from slaughter to sale.

Whether you’re processing beef, bison, pork, goats, sheep, poultry, deer, or other species, harvesting your animals onsite helps to ensure meat quality, lower transportation costs, and reduce your dependence on large packing plants.

Friesla’s Meat Processing Systems are interconnected modules that enable you to knock and bleed, harvest, chill, cut and package, freeze, store, and sell meat onsite. The systems are USDA-compliant and fully integrated with your HACCP plan.

Compared to building a brick and mortar facility, our Meat Processing Systems can be expanded, rearranged, or relocated as your operations grow. The systems are more cost-effective to operate than fixed facilities, requiring significantly less power, water, and other resources.

Unlike traditional brick and mortar plants, Friesla’s Meat Processing Systems are depreciable over 7 years. The time period from concept to operations is typically significantly shorter for a Modular Meat Processing System than designing, permitting, and building a brick and mortar facility. Friesla’s systems are delivered with hardware and software to support product traceability and digital workflows. Training on system use is provided by our team.

View our Meat Processing System models below or connect with us to learn more.

A Complete System

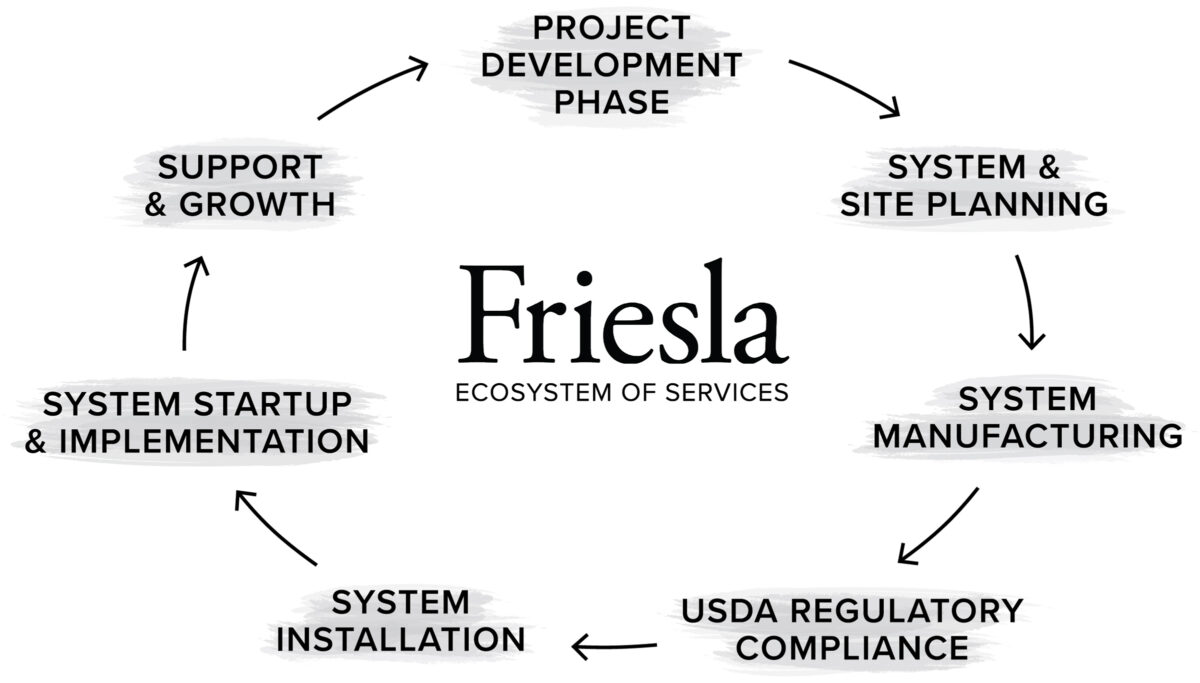

Friesla Meat Processing Systems are delivered to your site fully equipped and ready to operate after installation. Our team methodically works through the details—from design and manufacturing to installation and implementation—to provide you with an efficient, operational, USDA-compliant system at startup.

PS Starter Systems

Friesla’s PS Starter Systems are USDA-compliant Modular Meat Processing Systems for the onsite, small-scale processing of livestock.

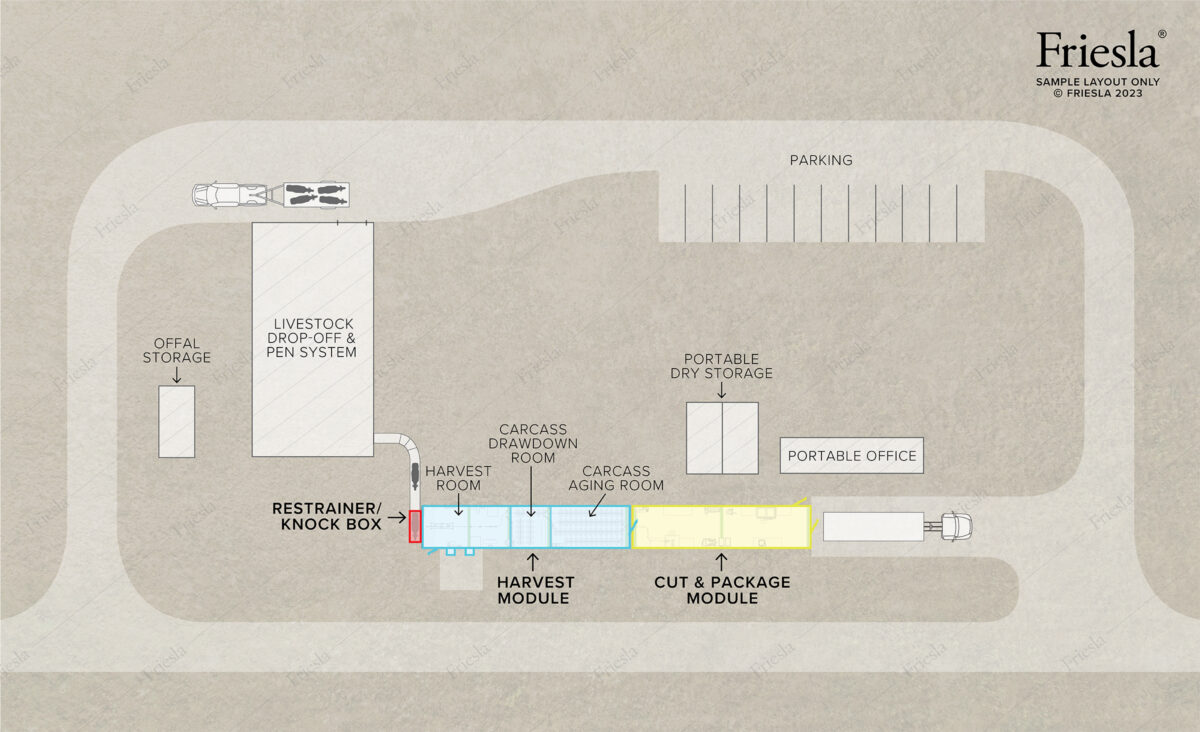

Purpose-designed for your operation and built in a modular format, Friesla’s PS Starter Systems consolidate the workspace from other standalone Friesla modules—such as a Meat Harvest Module, Carcass Aging Cooler, or Cut & Package Module—into an efficient footprint spanning 1 to 3 Friesla modules.

For example, Friesla designed and built a 2-module PS Starter System for a Native American tribe to process bison, incorporating a Harvest Room, Carcass Drawdown Room, and Carcass Aging Room into one 58’ module and tying it into a standalone 58’ Cut & Package Module.

Another meat processor needed to add a kill floor to augment their existing fabrication facility. They installed a 2-module Friesla PS Starter System to help close this gap. This enabled them to harvest, chill, and break down carcasses into primals for transfer to their fabrication facility in a neighboring county.

Friesla’s team designs your PS Starter System for your site location during a Project Development Phase—factoring in elements like a livestock pen system, offal storage, and office space—and walks with you through site responsibilities, preparation, and utilities information—from power and water to waste management. As part of the end-to-end solution, the PS Starter System is integrated with your Friesla-prepared HACCP Plans and fully outfitted with a meat processing equipment and consumables package specified for your operations.

Connect with us to explore designing and building your PS Starter System.

Get in Touch

PS-1 Systems

Friesla’s PS-1 Systems are USDA-compliant Modular Meat Processing Systems for the onsite, start-to-finish processing of up to 75 head of beef (or equivalent species) per week.

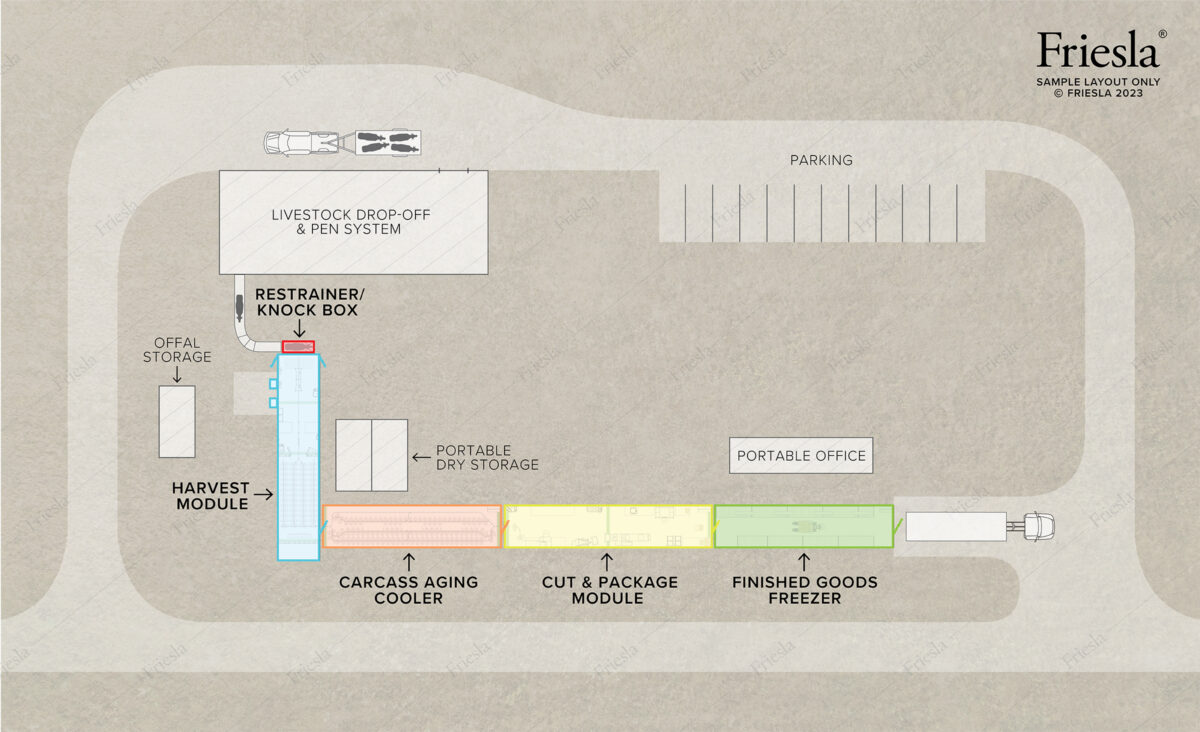

The PS-1 System’s efficient linear workflow gives you control from slaughter to sale—enabling you to knock, bleed, harvest, chill, cut, package, freeze, and store finished goods—under USDA, state inspection, or custom exemption. They are equipped for multi-species processing, enabling the harvest of beef, bison, pigs, goats, sheep, poultry, deer, and other species.

These scalable processing plants include four Friesla modules: a Meat Harvest Module with a Restrainer/Knock Box, Carcass Aging Cooler, Cut & Package Module, and Finished Goods Freezer. Each module is purpose-built in the USA and can include framed-in Expansion Ports for adding capacity as your operations grow. Dimensions may vary by project needs but Friesla PS-1 modules are generally 12’ wide, 50-58’ long, and 12’ tall.

During a Project Development Phase, Friesla’s team designs your PS-1 System for your site location—factoring in elements like a livestock pen system, offal storage, and office space—and walks with you through site responsibilities, preparation, and utilities information—from power and water to waste management. As part of the end-to-end solution, the PS-1 System is integrated with your Friesla-prepared HACCP Plans and fully outfitted with a meat processing equipment and consumables package specified for your operations.

Connect with us to explore designing and building your PS-1 System.

Get in Touch

PS-2 Systems

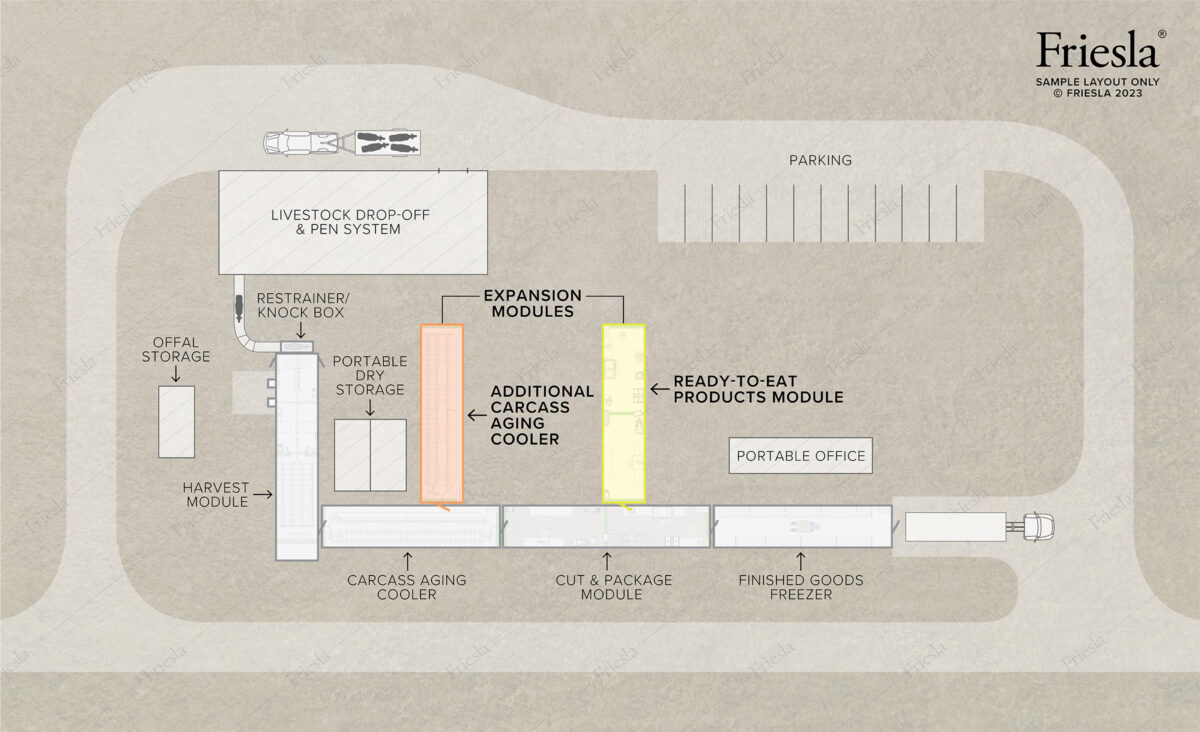

Friesla’s PS-2 Systems are USDA-compliant Modular Meat Processing Systems that add processing capacity and functionality to a Friesla PS-1 System by expanding its modular footprint.

For existing meat processors operating Friesla’s PS-1 System, PS-2 Systems enable you to scale up your plant to support your business’ growth. For example, they can incorporate additional Meat Harvest Modules to increase the slaughter capacity of a PS-1 System, Carcass Aging Coolers for added dry aging or hanging space, Cut & Package Modules for more carcass fabrication and packaging space, and Finished Goods Freezers for increased cold storage.

For meat processors who want to process more than 75 head of beef (or equivalent species) per week starting on day one, PS-2 Systems provide the building blocks for designing a higher-volume meat processing plant beyond the PS-1 System. For example, starting with two Carcass Aging Coolers for hanging capacity of up to 100 head of beef per week or incorporating a Ready-To-Eat (RTE) Products Module to produce high-margin value added products like bacon, ham, jerky, and sausage.

As with the PS-1 System, Friesla’s team designs your PS-2 System during a Project Development Phase. This incorporates your plant into your site location—factoring in elements like a livestock pen system, offal storage, and office space—and covers site responsibilities, preparation, and utilities information—from power and water to waste management. As part of the end-to-end solution, the PS-2 System is integrated with your Friesla-prepared HACCP Plans and fully outfitted with a meat processing equipment and consumables package specified for your operations.

Connect with us to explore designing and building your PS-2 System.

Get in Touch

PS-3 Systems

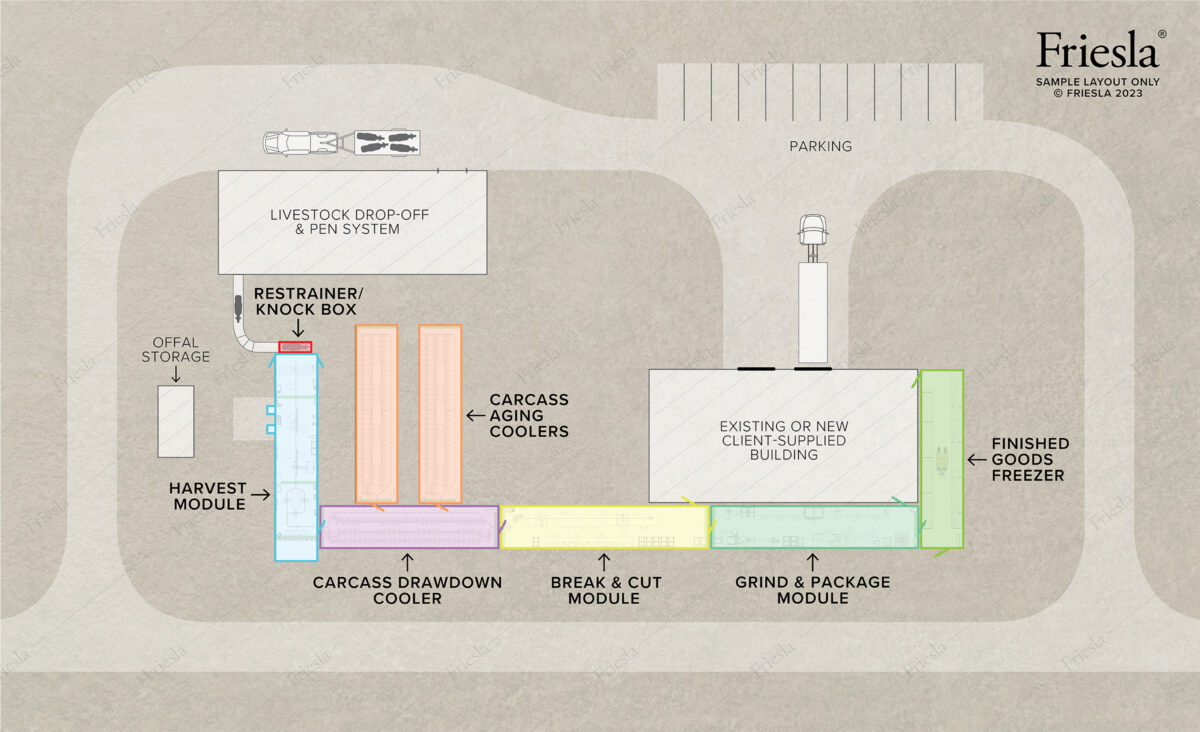

Friesla’s PS-3 Systems are USDA-compliant Modular Meat Processing Systems that integrate with client-supplied buildings—whether the buildings exist on the processing site or are a new build.

For meat processors who want to process higher volumes of animals per week beyond a PS-1 System or an expanded version of it, PS-3 Systems provide a plant with modules dedicated for each stage of production.

For example, replacing a Meat Harvest Module’s integrated 15-head Carcass Drawdown Room with a separate, standalone 50-head Carcass Drawdown Module. A scenario for high-volume carcass fabrication could entail splitting a Cut & Package Module into a standalone Break & Cut Module—solely for breaking down carcasses to primals—and a standalone Grind & Package Module—primarily for ground meat production and packaging.

As with the PS-1 System, Friesla’s team designs your PS-3 System during a Project Development Phase. This incorporates the plant into your site location—factoring in elements like a livestock pen system, offal storage, and office space—and covers site responsibilities, preparation, and utilities information—from power and water to waste management. As part of the end-to-end solution, the PS-3 System ties into your Friesla-prepared HACCP Plans and is fully outfitted with a meat processing equipment and consumables package specified for your operations.

Connect with us to explore designing and building your PS-3 System.

Get in Touch