When U.S. consumers purchase steaks, ground beef, or a Thanksgiving turkey, they expect it to be safe to eat. Today, the U.S. Department of Agriculture (USDA)’s Food Safety and Inspection Service (FSIS) works to ensure food safety—though their safety standards haven’t always existed.

In 1906, Upton Sinclair penned “The Jungle,” a novel which exposed shocking working conditions and poor sanitation in Chicago meat packing plants. Later that year, President Theodore Roosevelt signed the Federal Meat Inspection Act (FMIA) into law. This new legislation required all animals to be inspected by the USDA both before and after slaughter.

FROM SPACE TO HACCP

Sixty years later, the National Aeronautics and Space Administration (NASA) issued their own food safety guidelines to ensure the food consumed by astronauts was safe. Since testing food in space wasn’t an option, NASA needed an alternative approach. They already had testing procedures to ensure the reliability of critical space system hardware. In partnership with Pillsbury, NASA decided to apply the same concepts to food.

The space agency’s procedures were guided by three principles:

- Analyze the process and pinpoint where a type of hazard could occur

- Determine how each of those hazards could be prevented, controlled, or eliminated

- Monitor these critical points with frequent measurements

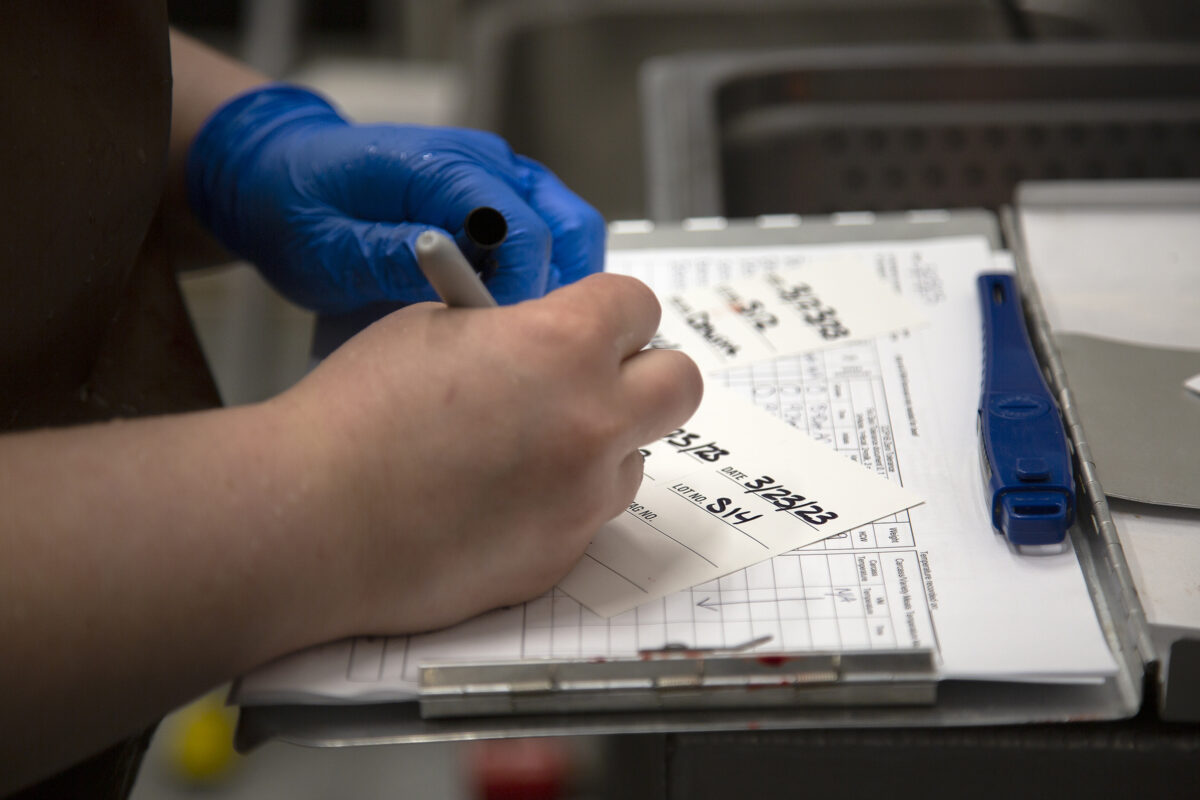

This model evolved and laid the foundation for today’s food industry standard: the Hazard Analysis Critical Control Point (HACCP) program. Through their HACCP programs, meat processors must demonstrate they’ve developed a preventative, systematic approach to eliminating hazards before, during, and after processing. Creating this control system isn’t a one-time event. It requires meat processors to maintain supporting documents, logs, corrective actions, and a routine of monitoring and record keeping.

HACCP HELP

Becoming—and remaining—compliant with these regulations can be intimidating. “Many meat processors see HACCP as a big, dark hole they need to navigate through,” explains Chris DePalma, Friesla’s food safety and regulatory compliance lead. “We shed light on the process by providing a flashlight, a map, and support to get to the other side.”

As a component of all Friesla equipment packages, Friesla’s Technical Team develops Food Safety Production Systems customized to each processor’s production goals—writing HACCP programs ranging from Slaughter and Raw Product–Intact (e.g., steaks and roasts) to Ready-To-Eat, Heat-Treated, Shelf-Stable products (e.g., beef jerky).

“Many meat processors see HACCP as a big, dark hole they need to navigate through. We shed light on the process by providing a flashlight, a map, and support to get to the other side.”

Chris DePalma, Friesla’s food safety and regulatory compliance lead

In parallel, Friesla’s Technical Team helps prepare the processor’s application for a USDA Grant of Inspection—a requirement to operate a federally-inspected meat processing facility—and to submit the application to USDA together with the processor’s written HACCP programs. Friesla shepherds this approval process through USDA and helps to communicate with the USDA’s regional Frontline Supervisor.

TRAINED TO DEFEND

Processors still need to understand—and be able to defend—their Food Safety Production System. As preparation, processing staff completes onsite, multi-day HACCP training with Friesla’s Technical Team to learn the why behind their HACCP protocols and how to properly implement them. This provides them tools to complete annual HACCP reassessments and to make required program revisions when their equipment or processes change. Upon completing training, attendees receive HACCP certification, enabling them to implement and reassess their program.

This side-by-side support doesn’t stop once a processor receives their USDA Grant of Inspection. Food safety plans are fluid and need to be updated as regulations evolve or new hazards emerge. Friesla’s Technical Team remains accessible as a HACCP “phone-a-friend”—a knowledgeable guide to help processors navigate and adapt to changes.

Food safety and regulatory compliance are critical for meat processing operations. Engage a partner who will help ensure both so you can focus on your business, team, and customers.

Learn more about Friesla’s Ecosystem of Services or connect with us here.