Animal welfare is a hot topic in today’s agricultural economy—and for good reason. Humane animal handling is a moral venture and carries high cultural expectations: from regulators enforcing humane handling laws and consumers enjoying meat products to the producers and processors running businesses to meet this demand.

Conversations about meat quality can often revolve around raising animals, from how they are bred to how they are fed. For food animals, how they are handled up to and during harvest is as critical to maintaining meat quality as was breeding and feeding them.

These handling practices also have spillover effects—both on the workers charged with safely tending animals and the companies responsible for bringing quality meat products to market.

HUMANE HANDLING REGULATIONS

From a legal perspective, the humane handling of livestock at U.S. slaughter facilities is required by the Humane Methods of Slaughter Act (HMSA). HMSA was passed by Congress in 1958 and is enforced by the USDA Food Safety and Inspection Service (FSIS).

The Code of Federal Regulations (9 C.F.R Part 313 Humane Slaughter of Livestock) outlines HMSA’s application and enforcement. It provides the nitty gritty details of humane handling leading up to and during slaughter, repeatedly emphasizing the overarching goals: minimizing livestock excitement, injury, and unnecessary pain.

GETTING & STAYING COMPLIANT

Ensuring humane handling during the livestock harvest process requires intention—and clear, detailed guidelines for the meat processors held to these standards.

Processors achieve a Robust Humane Handling Program through a written and systematic plan that includes training and routine audits, explains Chris DePalma, Friesla’s food safety and regulatory compliance lead. The written plan should be customized to the specific processing facility, regularly referenced by employees, and available for review by USDA FSIS.

As a component of each Friesla Meat Processing System, Friesla’s Technical Team develops a Robust Humane Handling Program customized for your processing operation. Foundational to each program is a Humane Handling Mission Statement:

“Our mission is to produce safe, wholesome, quality meat products for our customers. Recognizing the important role humane handling has in the overall quality of the end product, we are committed to ensuring the highest standards of respect for livestock animals destined for harvest. We have a moral obligation to safeguard these animals from unnecessary suffering and expect this attitude to be reflected and adhered to by all company personnel.”

Expanding on this mission statement, the other elements of the program include:

- A detailed risk assessment outlining potential challenges and mitigation steps—similar to your Friesla-provided Hazard Analysis and Critical Control Point (HACCP) Plans

- Standard Operating Procedures (SOPs) specific to your facility—e.g., truck unloading, penning, and stunning procedures

- Documentation of regular (weekly and quarterly) internal audits, including logs of corrective actions that have been implemented

- Ongoing humane handling training for employees

A SYSTEM FOR HUMANE HANDLING

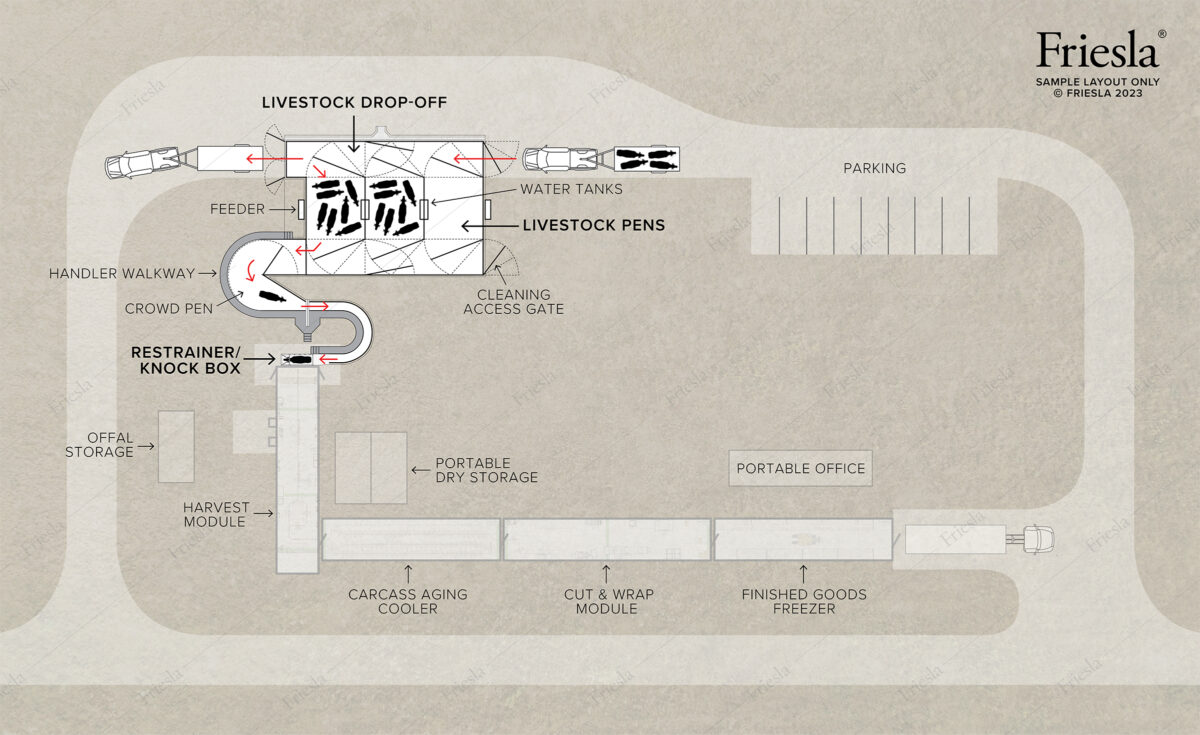

Meat processors ensure livestock welfare by properly implementing their Robust Humane Handling Programs. Doing so requires physical infrastructure—a well-designed pen system that enables processors to safely, humanely, and efficiently move animals.

As part of Friesla’s System & Site Planning Services, our Humane Handling Pen System Design process yields blueprints for livestock pens tailored to your operations. This helps processors:

- Comply with Federal regulations for humane handling

- Adhere to your Robust Humane Handling Program

- Align with humane handling behavioral principles advocated by the North American Meat Institute and industry leaders like Dr. Temple Grandin and Mark Deesing

These blueprints help set the foundation for a streamlined meat processing operation. During the design process, Friesla’s Technical Team incorporates factors including:

- Site-specific considerations (e.g., location of restrainer/knock box, animal drop off area)

- Animal flow based on natural livestock tendencies—from unloading/receiving to staging and restraining for harvest

- Pen organization to minimize animal stress and maximize available space

- Specification of materials to provide livestock with secure footing and avoid slips/falls (e.g., grooved concrete)

- Employee safety while moving animals within the pen system (e.g., handler walkways, alley and man gates)

- Ability to hold different livestock species & sizes (e.g., beef, sheep, goats, pigs)

- Flexibility to hold suspect animals (e.g., covered pen space for ensuring regulatory compliance)

- Access to water & feed (e.g., water at all times and feed when animals are held over 24 hours)

- Gates for easy manure removal

- Gates for removal of euthanized livestock (e.g., non-ambulatory, condemned animals)

Respect and care for livestock is critical to meat producers’ and processors’ long-term success. Engage a partner with a strong commitment to humane handling—and the resources to help your team set and maintain this standard.

Learn more about Friesla’s Ecosystem of Services or connect with us here.